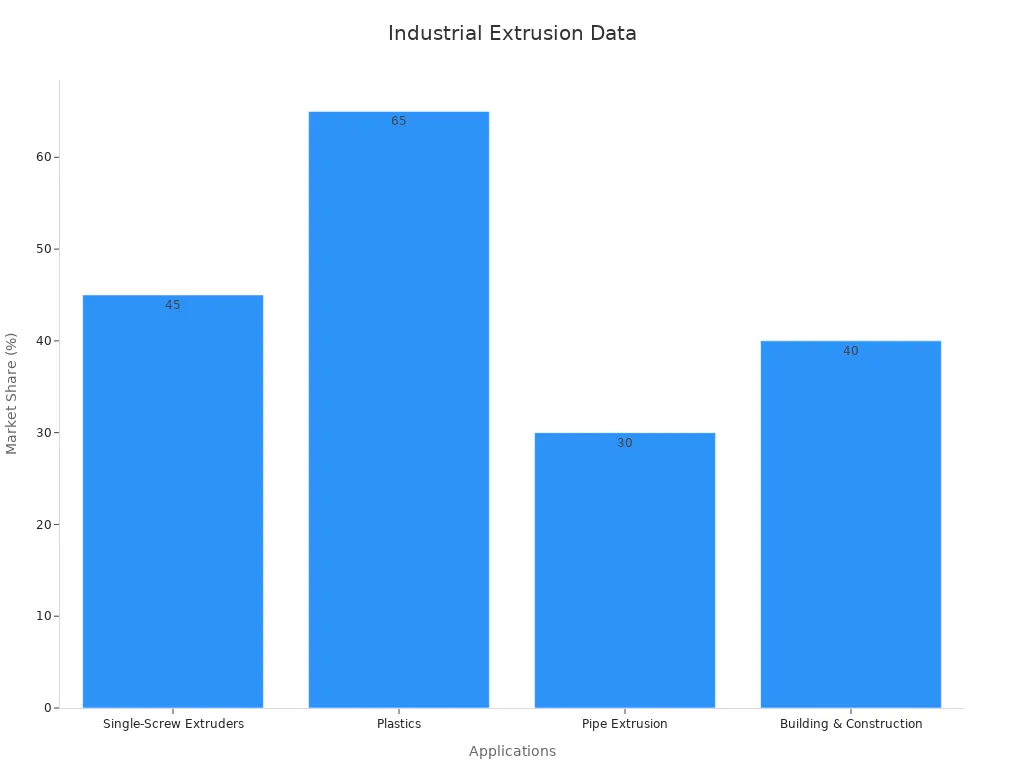

Hoʻohana ʻia ka extrusion wili hoʻokahi i hoʻokahi wili wili hoʻokahi, ʻoiai ke hilinaʻi nei ka extrusion māhoe māhoe ma luna o ʻelua wili intermeshing no ka hoʻonui ʻana i ka hui ʻana. Hoʻopili kēia ʻokoʻa i ka maikaʻi o ka huahana a me ka mana kaʻina hana. No ka hana maʻalahi, ka nui-nui, aBarela Screw Plastic Singlekūpono i ka nui o nā pono.Nā Barela Mālua Screw ExtruderaʻO nā māhoe māhoe no nā mea hoʻoheheʻe palakimaikaʻi i ka hui ʻana paʻakikī.

Ua wehewehe ʻia ka Extrusion Screw hoʻokahi

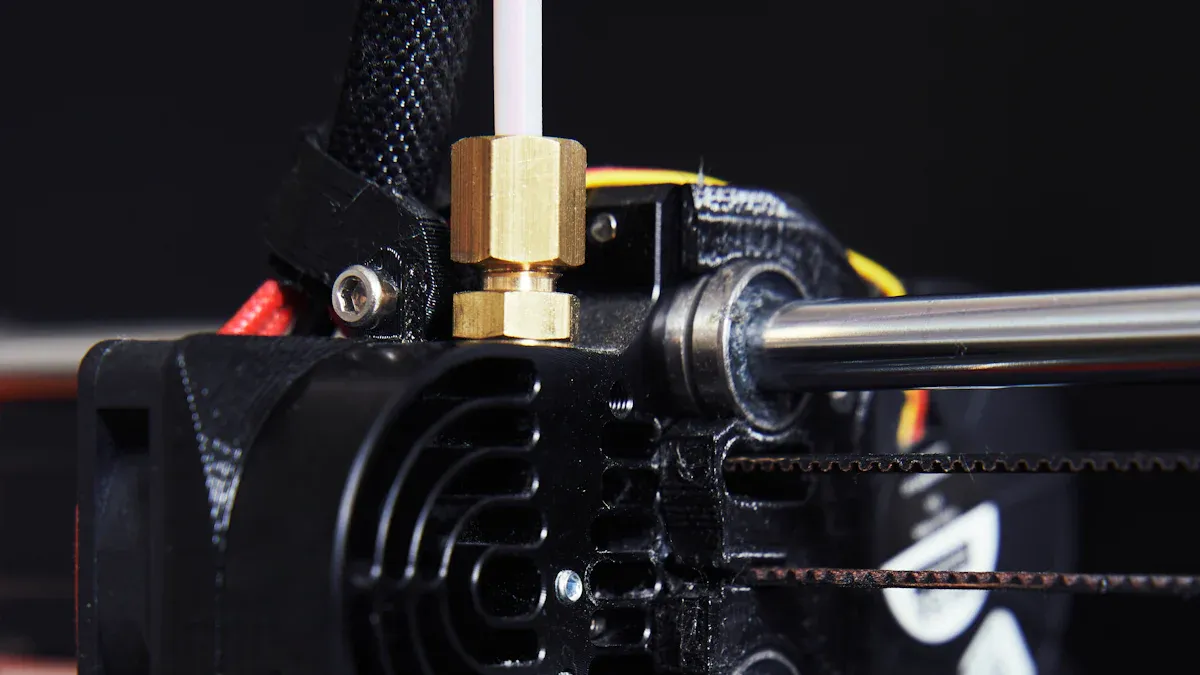

Pehea e hana ai ka Extrusion Screw hoʻokahi

Hoʻohana ka hoʻoheheʻe ʻana i hoʻokahi wiliwili hoʻokahi i loko o kahi pahu wela. Hoʻoneʻe ka wili i ka ʻilika maka a i ʻole ka mea hao i mua, kahi e hoʻoheheʻe ai ka friction a me ka wela. Hele ka mea hehee i loko o ka make e hana i ke ʻano mau. Hoʻoponopono nā mea hana i nā ʻāpana kaʻina hana nui e like me ka wela o ka barela (maʻamau 160–180 °C), ka wikiwiki o ka wili, a me ka wela make. ʻO ka wikiwiki o ka ʻāpana lawe a me ka mahana pahu wai e kōkua i ka hoʻomalu ʻana i ke anawaena a me ka hoʻoluʻu o ka huahana hope. Hana ka wiliʻekolu mau hana nui: lawe, hoʻoheheʻe, a hui pū. Hoʻolālā barelaʻO nā hiʻohiʻona e like me ka paʻakikī paʻakikī a me ka chrome plating e hōʻemi i ka friction a me ka pili ʻana, e hōʻoia i ka hana maʻemaʻe.

ʻO nā pono o ka Extrusion Screw hoʻokahi

Koho nā mea hanahoʻokuʻu hoʻokahi wilino ka maʻalahi a me ke kumukūʻai. Hiki i ka hoʻolālā ke hana maʻalahi a mālama. ʻO ka haʻahaʻa haʻahaʻa o ka hoʻopukapuka mua a me nā kumukūʻai hana e hoʻonani ia i nā ʻoihana he nui.ʻO ka ikaika o ka ikehukū i waho, ʻoiai ke hoʻohana nei ka ʻōnaehana i ka hoʻomehana maikaʻi ʻia a me ka liʻiliʻi o nā ʻāpana neʻe. Hiki i nā mea hana ke hoʻokō i ka maikaʻi o ka huahana ma o ka hoʻoponopono ʻana i ka mahana, ke kaomi, a me ka wikiwiki o ka screw. Hoʻohana ka ʻōnaehana i ka nui o nā mea maka, e hoʻolilo iā ia i mea maʻalahi no nā pono hana like ʻole.

Manaʻo kōkua: ʻO ka mālama mau ʻana a me ka nānā ʻana i ka ikehu manawa maoli hiki ke hoʻomaikaʻi hou i ka maikaʻi a me ka maikaʻi o ka huahana.

Nā palena o ka hoʻokuʻu ʻia ʻana o ka Screw hoʻokahi

Ke kū nei ka extrusion hoʻokahi screw i kekahi mau pilikia. Hiki ke paʻa ʻole ka throughput i ka wikiwiki wili, e kaupalena ana i ka nui o ka hana. Hiki ke paʻakikī ka mālama ʻana i ka mahana hehee a me ka homogeneity huahana, ʻoi aku me nā mea paʻakikī. Paʻakikī paha ke kaʻina hana me ka hui ʻana a i ʻole nā ʻano hana e pono ai ka mana pololei. ʻO ka hana hānai a me ka hoʻokomo ʻana e hilinaʻi nui ʻia i ka hoʻolālā screw a me ka geometry wehe.

Nā noi maʻamau o ka Extrusion Screw hoʻokahi

Loaʻa ka hoʻohana ʻana i ka extrusion hoʻokahi screw i nā ʻoihana he nui. Ke alakaʻi nei ʻo Packaging i ka mākeke, me kahi o 60% kaʻana, e hana ana i nā kiʻiʻoniʻoni a me nā pepa mai nā polymers e like me PE, PP, a me PVC. Hoʻohana ka ʻāpana hana no nā paipu a me nā profiles, ʻoiai ke hilinaʻi nei nā mea hana automotive iā ia no nā ʻāpana o loko a me waho. Pono pū nā ʻoihana lapaʻau, nā mea kūʻai aku, a me nā ʻoihana uila mai kēia ʻenehana.

| ʻAno hoʻohālike | Ka Anawaena Uila (mm) | L:D ratio | Ka mana kaʻa (kW) | Hiki ke hoʻopuka (kg/hr) | Nā memo no ka Efficiency and Standards |

|---|---|---|---|---|---|

| Kiekie Efficient Single Screw | 60 – 120 | 38:1 | 110 – 315 | 465 – 1300 | 20-30% kiʻekiʻe kiʻekiʻe; Nā motika AC Siemens, CE-hōʻoia |

| ʻO ka maʻamau maʻamau hoʻokahi wili | 60 – 120 | 33:1 | 55 – 315 | 150 – 900 | Nā ʻāpana ʻano maʻamau |

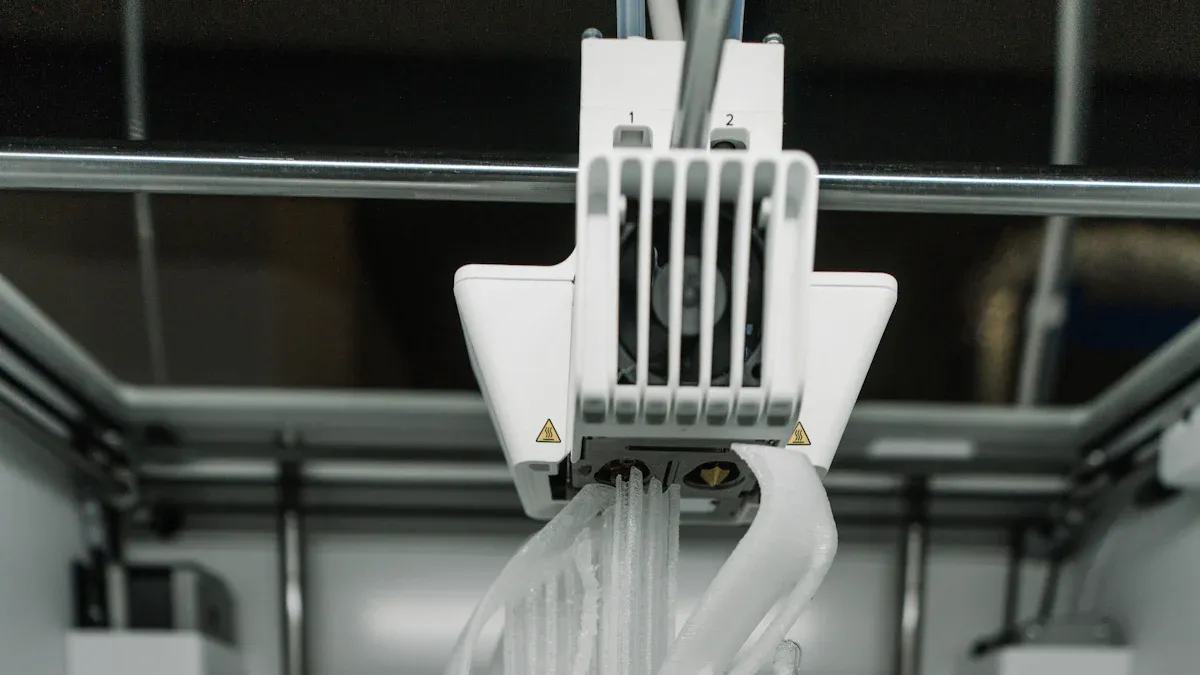

Nānā Hoʻokuʻu ʻia ʻo Twin Screw Extrusion

Pehea e hana ai ka Twin Screw Extrusion

Extrusion māhoe māhoehoʻohana i ʻelua wili intermeshing e hoʻololi i loko o kahi pahu wela. Hāpai nā mea hana i nā mea maka e like me nā pellets a i ʻole nā palaka i loko o ka hopper. E hoʻoneʻe nā wili i ka mea i mua, e hoʻopiʻi a kāwili ʻia. ʻO ka wela mai ka barela a me ka friction mai nā wili e hoʻoheheʻe i ka mea. Hoʻohui ʻia nā mea wili kūikawā a homogenize i ka heheʻe, e hōʻoia i ka hoʻopuehu ʻana o nā mea hoʻohui. A laila hele ka mea hoʻoheheʻe i loko o kahi make e hana i ka huahana hope. ʻO nā barela modular me nā wahi hoʻomehana a me nā ʻāpana hoʻoluʻu e ʻae i ka hoʻomalu ʻana i ka mahana. Hoʻokuʻu ʻia nā ea a me nā volatiles, hoʻomaikaʻi i ka maikaʻi o ka huahana.

Ka ikaika o Twin Screw Extrusion

Hāʻawi ka twin screw extrusion i nā pono he nui:

- ʻOi aku ka hui ʻana a me ka homogenization ma muli o nā wili intermeshing.

- ʻO nā ikaika ʻāwīwī kiʻekiʻehoʻomaikaʻi i ka hui ʻana a me ka like ʻana o ka huahana.

- Hiki i ka hoʻolālā modular ke hoʻololi maʻalahi no nā mea like ʻole.

- ʻO ka hoʻonui ʻana i ka mahana wela e hōʻemi i ka hoʻohaʻahaʻa wela.

- Kākoʻo ka hana kiʻekiʻe a me ka huahana i ka hana nui.

- ʻO ka hoʻonohonoho ʻana i nā ʻōkuhi maʻalahi e hoʻoikaika i ka hana ʻana no nā polymers like ʻole.

- ʻOi aku ka maikaʻi o ke kaʻina hana me ka hoʻoponopono kūʻokoʻa o ka wikiwiki a me ka mahana.

- ʻOi aku ka lōʻihi o ke ola ʻana o nā mea hana ma ke kaʻana like ʻana o ka ukana ma waena o ʻelua wili.

| ʻAno ʻenehana | wehewehe |

|---|---|

| ʻO ka hui ʻana a me ka homogenization | Hoʻokumu ʻia nā wili intermeshing i nā hopena shear a kneading no ka hui like ʻana. |

| Kiʻekiʻe Loaʻa & Huahana | Hiki i nā wiliwili hui ke hoʻonui i ka hana a me ka pono. |

| ʻAno ʻano | Hiki iā ia ke hana i nā polymers like ʻole a me nā hana paʻakikī. |

Nawaliwali o Twin Screw Extrusion

- He ʻano paʻakikī ko twin screw extruders a ʻoi aku ke kumukūʻai.

- He paʻakikī ke hoʻohālike a wānana ke kahe o nā mea i loko o ka extruder.

- Hiki ke loli ke kaomi ma muli o ke ʻano geometry.

- ʻO ka nānā ʻana i ka nui o nā ʻāpana a me ka paʻa o ke kaʻina hana he pilikia.

- ʻO ka hoʻonui ʻia ʻana mai ka lab a i ka hana ʻana pono e hoʻoponopono pono.

Hoʻohana maʻamau no ka Extrusion Screw Twin

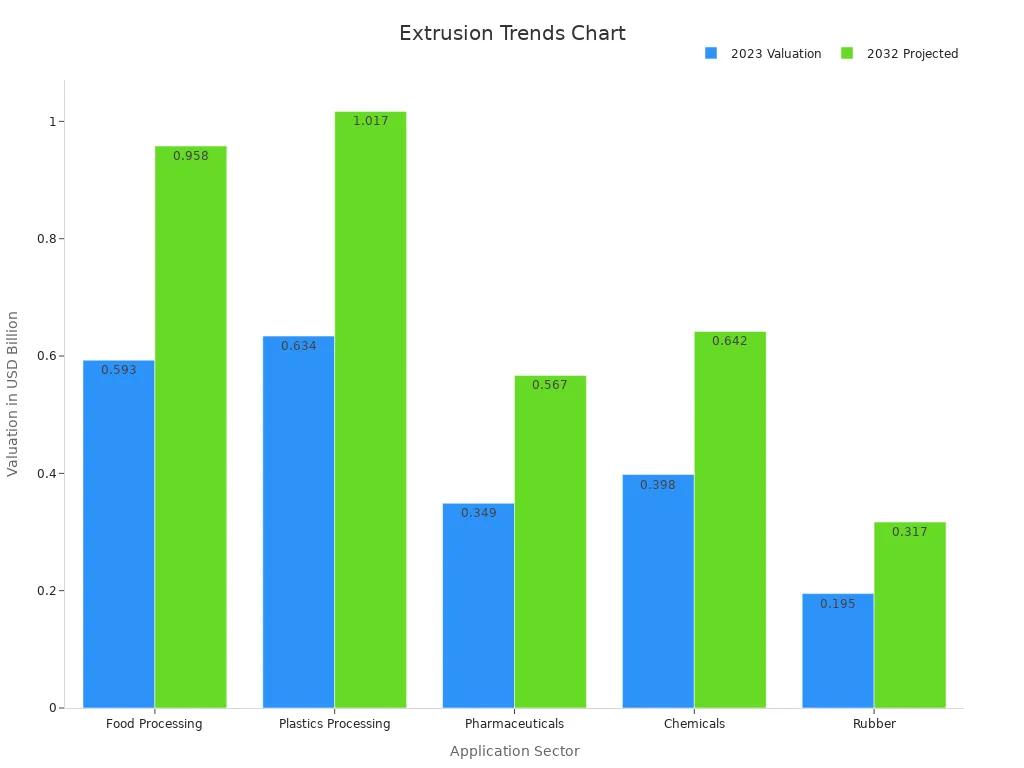

He kuleana koʻikoʻi nā extruder twin screw i nā ʻoihana he nui. Hoʻohana nā mea hana iā lākou no ka hoʻohui ʻana i nā plastics, ka hana ʻana i nā mea hana hou, a me ka hana ʻana i nā bioplastics. Ke hilinaʻi nei ka ʻoihana meaʻai iā lākou no nā meaʻai, cereals, a me nā meaʻai holoholona. Hoʻohana nā hui lāʻau lapaʻau i ka twin screw extrusion no ka hana ʻana i nā ʻano ʻano paʻa. Loaʻa ka pōmaikaʻi o nā ʻāpana kemika a me ka lāʻau mai kā lākou hui ʻana a me ka hoʻomalu. Ke hoʻomau nei ka mākeke no nā twin screw extruders, i alakaʻi ʻia e ka noi ma Asia-Pacific, Europe, a me ʻAmelika ʻAmelika.

Hoʻokahi Screw Extrusion vs Twin Screw Extrusion: Nā Hoʻohālikelike Nui

Hoʻolālā a me Mechanism ʻokoʻa

Hoʻokuʻu hoʻokahi wilihoʻohana i hoʻokahi wili wili me kahi ʻano helical maʻalahi. Hoʻopuka kēia hoʻolālā i nā mea i mua ma o ka pahu. ʻO ka ʻokoʻa, loaʻa nā extruders māhoe ʻelua i ʻelua mau wili intermeshing. Hiki i kēia mau wili ke hoʻololi i nā ʻaoʻao like a i ʻole ʻē aʻe a hoʻokomo pinepine i nā poloka kneading no ka hui ʻana maikaʻi. Hōʻike ka papa ma lalo nei i nā ʻokoʻa ʻenehana nui:

| Aspect | Hookahi Screw Extruder | Mālua Screw Extruder |

|---|---|---|

| Hoʻolālā Screw | ʻO ka wili wili hoʻokahi me ke ʻano helical maʻalahi e hoʻohuli ana i nā mea i mua. | ʻElua wili intermeshing, hiki ke hui pū a i ʻole ka huli ʻana, me nā geometries paʻakikī me nā poloka kneading. |

| Hiki ke huikau | He kūpono no nā mea homogeneous a me ka hui maʻalahi. | ʻOi aku ka maikaʻi o ka hui ʻana ma muli o ka intermeshing screws, hiki ke hoʻopuehu maikaʻi i nā mea hoʻohui a me nā mea hoʻopiha. |

| Hoʻopuka a me ka hoʻopuka | Haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa. | ʻOi aku ka nui o ka throughput a me ka hoʻopuka, kūpono no ka hana nui. |

| Hoʻomalu wela | Ka mana kumu ma luna o ka wela, ka māmā holo, a me ke kaomi pahu. | Hoʻonui ʻia ka hoʻoponopono ʻana i ka wela me nā ʻāpana hoʻomehana/hoʻoluʻu kūloko ma ka pahu. |

| Hooponopono Mea | Pono no nā thermoplastics, elastomers, a me nā plastic recycled me ka maikaʻi o ka huahana. | ʻOi aku ka maikaʻi no nā mea hoʻohālikelike kiʻekiʻe-viscosity, wela, a paʻakikī e koi ana i ka mana pololei. |

| Hoʻololi i ke kaʻina hana | ʻOi aku ka maʻalahi, ka hana maʻalahi a me ka mālama ʻana. | ʻOi aku ka maʻalahi ma muli o ka hoʻolālā modular screw a me nā ʻāpana hiki ke hoʻololi ʻia. |

| Hiki ke hoʻoheheʻe ʻia | Hiki i ka degassing palena a me ka devolatilization. | ʻO ka degassing maikaʻi a me ka devolatilization, mea nui no ka mālama maikaʻi. |

| Nā Laʻana Hoʻohana | ʻO nā kiʻiʻoniʻoni plastik, nā paipu, ka hui ʻana, ka uhi uea, ka extrusion pepa, ka hana ʻai. | ʻO ka hoʻohui ʻana o ka polymer, ka hoʻoili ʻana i ka meaʻai, nā lāʻau lapaʻau, a me ka hoʻoili waiwai paʻakikī. |

ʻO nā mea noiʻi e like me Shen et al. a me Sastrohartono et al. ua hōʻike i nā māhoe screw extruders e hāʻawi i nā hiʻohiʻona hoʻolālā kiʻekiʻe, e like me ka ʻoi aku ka maikaʻi o ka shear flux a me ka ikaika o ka ikehu, ʻoi aku ka nui o nā mea paʻakikī.

Hiki i ka hui ʻana a me ka hana ʻana

Hoʻokaʻawale kēia mau ʻenehana ʻelua i ka hui ʻana a me ka hana ʻana. Hana maikaʻi ka extrusion hoʻokahi no nā mea maʻalahi, homogeneous. Hiki iā ia ke hana i nā hana hoʻohuihui maʻamau, akā paʻakikī me ka hui ʻana a i ʻole nā formation e koi ai i ka mana pololei. ʻOi aku ka maikaʻi o nā extruders twin screw i ka hui ʻana. Hoʻokumu ko lākou mau ʻāwili intermeshing i nā hopena ʻāwili a me ka hui ʻana. Mālama kēia hana i ka hoʻopuehu ʻana o nā mea hoʻohui a me nā mea hoʻopihapiha, he mea koʻikoʻi ia no nā huahana kiʻekiʻe. Hiki i nā mea hoʻohana ke hoʻoponopono i nā mea hoʻokalakupua a me nā ʻāpana barela e hoʻoponopono maikaʻi i ke kaʻina hana no nā mea like ʻole. ʻO ka hopena, kākoʻo nā ʻōnaehana māhoe māhoe i nā ʻōkuhi paʻakikī a koi i nā koi hana.

Noʻonoʻo: No nā mea hana pono e hoʻohui i nā polymers he nui a hoʻohui paha i nā mea hoʻopihapiha, hāʻawi nā twin screw extruders i kahi pōmaikaʻi i ka hui ʻana i ka hana.

Hoʻokomo a me ka pono

He kuleana nui ka throughput a me ka pono i ke koho ʻana ma waena o kēia mau ʻōnaehana. Hāʻawi pinepine ka extrusion screw hoʻokahi i ka haʻahaʻa haʻahaʻa, kūpono ia no nā pahuhopu hana liʻiliʻi. Hoʻohana ia i ka wikiwiki o ka hana ʻana a hāʻawi i nā hopena kūlike no nā huahana maʻamau. ʻO Twin screw extruders, ma ka ʻaoʻao ʻē aʻe, e hoʻokō i ka throughput kiʻekiʻe a me ka wikiwiki o ka hana ʻana. Kākoʻo lākou i nā koi mana nui a mālama i ka maikaʻi o ka huahana me ka granulation paʻakikī. Hoʻohālikelike ka papa ma lalo i nā ana nui:

| Metric | Hookahi Screw Extruder | Mālua Screw Extruder |

|---|---|---|

| Ka holo ana | Haʻahaʻa throughput, kūpono no ka haʻahaʻa hana pahu hopu | ʻO ka throughput kiʻekiʻe, kūpono no nā koi mana nui |

| Ka māmā holo | ʻOi aku ka māmā o ka hana ʻana | ʻOi aku ka wikiwiki o ka hana ʻana |

| ʻAno Huahana | ʻO ka ikaika o ka hui pū ʻana, ʻoi aku ka paʻakikī o ka granulation | Hoʻonui i ka hui ʻana, kākoʻo i ka granulation paʻakikī |

| Na koina hana | ʻO nā kumukūʻai hana haʻahaʻa ma muli o ka maʻalahi a me ka pono o ka ikehu | ʻOi aku ka nui o nā kumukūʻai hana ma muli o ka paʻakikī a me ka mālama ʻana |

| ʻoluʻolu | ʻAʻole hiki ke maʻalahi, hana maʻalahi | ʻOi aku ka maʻalahi, hiki ke mālama i nā formulations paʻakikī |

| Uku Huna | ʻO ka maʻamau e hoʻohaʻahaʻa i nā uku hoʻopuka | ʻOi aku ka nui o nā uku hoʻopuka |

Hoʻomaopopo pinepine nā twin screw extruders i kā lākou kumukūʻai kiʻekiʻe me ka hoʻonui ʻana i ka huahana a me ka hiki ke mālama i nā mea paʻakikī.

Hoʻololi a me ka Versatility

Pono ka maʻalahi a me ka versatility no ka hana hou. Hāʻawi ka extrusion screw hoʻokahi i ka hana hilinaʻi no nā huahana maʻamau a me nā mea. Eia nō naʻe, hāʻawi ia i ka maʻalahi i ka wā e hoʻololi ai i waena o nā ʻano hana like ʻole a i ʻole nā ʻano huahana. Kūlana nā extruder māhoe māhoe ma kēia wahi. Ma ka hōʻike kālepa K 2016, hōʻike nā laina māhoe māhoe kiʻekiʻe i nā loli wikiwiki ma waena o nā mea waiwai, nā kala, a me nā mānoanoa. Ua hoʻololi kekahi mau ʻōnaehana i nā ʻano i nā minuke, ʻaʻole i nā hola. Hoʻoponopono kēia mau extruders i nā kiʻiʻoniʻoni multi-layer a hiki i 11 mau papa, e lawelawe ana i nā mea e like me EVOH, nylon, a me nā māka polyethylene like ʻole. Ua hōʻike ʻia ka ʻikepili hana a45.8% ka emi ʻana o ka ʻōpala waiwaia kokoke i 29% ka mālama ʻana i ka ikehu ma hope o ka hoʻonui ʻana i nā ʻōnaehana māhoe māhoe maʻalahi. Ua hoʻopōkole ʻia ka hoʻihoʻi ʻana i ka manawa hoʻopukapuka ma luna o 26%. Hōʻike kēia mau hoʻomaikaʻi ʻana i nā pono hana o nā extruder māhoe māhoe i loko o nā kaiapuni paʻakikī, multi-material.

Kumukuai a me ka Manaʻo Noʻonoʻo

Hoʻopili ke kumukūʻai a me ka mālama ʻana i ka hoʻoholo hope loa no nā mea hana he nui. He emi ke kumu kūʻai a me ka hana ʻana i nā ʻōnaehana extrusion screw hoʻokahi. ʻO kā lākou hoʻolālā maʻalahi ʻo ia ka liʻiliʻi o nā ʻāpana e mālama a hoʻohaʻahaʻa i ka hoʻohana ʻana i ka ikehu. He maʻalahi ka mālama maʻamau, a he liʻiliʻi ka manawa hoʻomaha. Pono nā extruders māhoe māhoe i kahi hoʻopukapuka mua kiʻekiʻe. ʻO kā lākou hana paʻakikī a me nā hiʻohiʻona kiʻekiʻe e alakaʻi i ka hoʻonui ʻana i nā pono mālama a me ka hoʻohana ʻana i ka ikehu kiʻekiʻe. Eia nō naʻe, no nā ʻoihana e hana ana i nā huahana kiʻekiʻe a paʻakikī paha, ʻoi aku ka nui o nā pono o ka maʻalahi, throughput, a me ka maikaʻi ma mua o nā kumukūʻai keu. ʻO ke koho ʻana i ka ʻōnaehana kūpono e pili ana i ke kaulike ʻana i kēia mau mea me nā pahuhopu hana a me ka waihona kālā.

Ke koho ʻana i ka Extruder kūpono no kāu mau pono

Pono Mea Pono

Hoʻomaka ke koho ʻana i ka extruder kūpono me ka hoʻomaopopo ʻana i ka hoʻohālikelike o nā mea. ʻO nā mea mīkini nui e like meka māmā holo, anawaena, a me ka ratio lōʻihi-a-anawaenapili i ka hana o ka extruder i nā mea like ʻole. No ka laʻana, kōkua nā lakio L/D kiʻekiʻe me nā mea paʻakikī e pono ai ka hoʻoheheʻe ʻana a me ka hui ʻana. Kākoʻo ka hoʻolālā barrel, me nā ʻāpana wela a me ka hoʻokuʻu ʻana, i nā mea koʻikoʻi a i ʻole i hana hou ʻia. Manaʻo nā alakaʻi ʻoihana e hoʻohālikelike i ka extruder me ka wela o ka hana ʻana o ka mea, viscosity, a me ke kahe kahe. Hoʻohana maikaʻi ka extrusion hoʻokahi no ka hana nui o nā thermoplastics, ʻoiai nā twin screw extruders e lawelawe i nā hana paʻakikī i ka meaʻai, lāʻau lapaʻau, a me nā ʻoihana polymer.

Pākuʻi Hana a me ka Hoʻopuka

ʻO ka pālākiō hana a me nā koi hoʻopuka ke kuleana nui i ke koho extruder. Hiki ke hoʻonui i ka hoʻohana ʻana i ka ikehu a me ka pono o ka mālama ʻana. Hāʻawi ka hoʻonohonoho ʻana i nā screw modular no ka scalability maikaʻi a me ka hana. Hōʻike nā haʻawina i kēlāthroughput a hoʻopiha i ka pae hopena i ka maikaʻi o ka huahana a me ka hoʻohui ʻana i ka pono. Pono nā extruders nui e hoʻoponopono pono i nā ʻāpana hana e mālama i nā hopena kūlike. Pono nā ʻoihana e kaulike i nā pahuhopu hana me nā koina hana a me ka paʻakikī ʻenehana.

Puke kālā a me nā kumu kūʻai

ʻO nā kumukūʻai noʻonoʻo e pili ana i nā lilo mua a me ka hoʻomau. Hōʻike ka papa ma lalo nei i nā kumu waiwai nui:

| Kumukuai | wehewehe | Ka hopena kālā |

|---|---|---|

| Kūʻai mua | He ʻokoʻa ka nui a me ke ʻano | Hoʻokomo kālā mua |

| Palapala hōʻoia | ISO 9001, CE, etc. | Hiki ke hoʻonui i ke kumukūʻai kūʻai |

| Mālamalama | Pono ka lawelawe mau | Uku makahiki mau |

| Hoʻohana i ka ikehu | Mālama nā kumu hoʻohālike kūpono i nā koina no ka wā lōʻihi | Kiʻekiʻe i mua, haʻahaʻa i kēlā me kēia mahina |

| Hoʻomaʻamaʻa | Pono no ka hana pono | 1-3% o ke kumu kūʻai |

Loaʻa pinepine nā mea hana ma Asia-Pacific i nā kumukūʻai haʻahaʻa haʻahaʻa ma muli o nā pono kūloko.

Nā Manaʻo Hoʻopono

I ka manawake koho ʻana i kahi ʻōnaehana extrusion, pono nā hui e noʻonoʻo i ka nui o ka hana, ka maʻalahi o ka mea hoʻolako, a me nā koi o ka maikaʻi. No nā huahana maʻamau a me nā holo liʻiliʻi, hāʻawi ka extrusion screw hoʻokahi i ka maʻalahi a me nā kumukūʻai haʻahaʻa. Hoʻopili nā twin screw extruders i nā huahana kiʻekiʻe, paʻakikī, a i ʻole nā huahana hou e pono ai ka hui ʻana a me ka maʻalahi. ʻO nā ʻoihana e like me ka automotive, meaʻai, a me nā lāʻau lapaʻau makemake pinepine i nā ʻōnaehana twin screw no kā lākou versatility a me ka maikaʻi o ka huahana. Hiki i nā ʻoihana e ʻimi ana i ka ʻokoʻa mākeke ke hoʻololi i ka twin screw extrusion e hoʻokō i nā hiʻohiʻona huahana kūʻokoʻa.

- Nā mea hoʻoheheʻe māhoe māhoee hoʻohana i ʻelua wili no ka hui ʻana maikaʻi a me ke kahe waiwai paʻa.

- Lawe lākou i nā ʻano mea waiwai a hāʻawi i ka ʻoihana kiʻekiʻe.

- ʻOi aku ka maikaʻi o ka extrusion wili hoʻokahi no nā mea maʻalahi, haʻahaʻa-viscosity.

- No nā huahana paʻakikī a ʻoi aku ka maikaʻi, pono nā ʻoihana e koho i nā extruder twin screw.

FAQ

He aha ka ʻokoʻa nui ma waena o hoʻokahi wili a me twin screw extrusion?

Hoʻohana ka extrusion wili hoʻokahi i hoʻokahi wili no ka hana maʻamau. Hoʻohana ka twin screw extrusion i ʻelua wili no ka hui ʻana a me ka lawelawe ʻana i nā mea paʻakikī.

ʻO wai ka extruder maikaʻi loa no ka hana hou ʻana i nā plastic?

ʻOi aku ka maikaʻi o ka hoʻohana ʻana o nā extruders twin screw i nā plastic recycled. Hāʻawi lākou i ka hui ʻana a me ka hoʻomalu maikaʻi, e hoʻomaikaʻi ai i ka maikaʻi o ka huahana.

Pehea ka hoʻohālikelike ʻana o ka mālama ʻana ma waena o nā ʻano ʻelua?

Pono nā extruders hoʻokahi screw i ka mālama liʻiliʻi.Pono ka nānā ʻana i nā extruder māhoe māhoema muli o kā lākou hoʻolālā paʻakikī a me nā ʻāpana ʻē aʻe.

Ka manawa hoʻouna: Jul-08-2025